Tell us about the inception of WATSAN to design water filters and modular toilets?

In my travels around my state in India, I came across the lack of availability of potable water in rural areas and noticed that the need for infrastructure to address open defecation was what villagers needed most. Combined with my love of materials science, I have always been amazed with the type of ancient materials our rulers used to build the heritage temples and realized that Mother Nature has given us the best and immunized way of filtering and treating water. Clay and sand. So along with a few friends, I started a NGO called REACH foundation and began documenting the unknown temples that were lying uncared. After five years of research and fine-tuning the right technology for purification and building toilets, WATSAN was founded in 2013. Today, we have provided products to 2.15 million households in almost 18 states, mostly rural hamlets, border security posts of the Indian Army, child care centers, schools and public health centers.

Tell us more about the design component of your water filtration product?

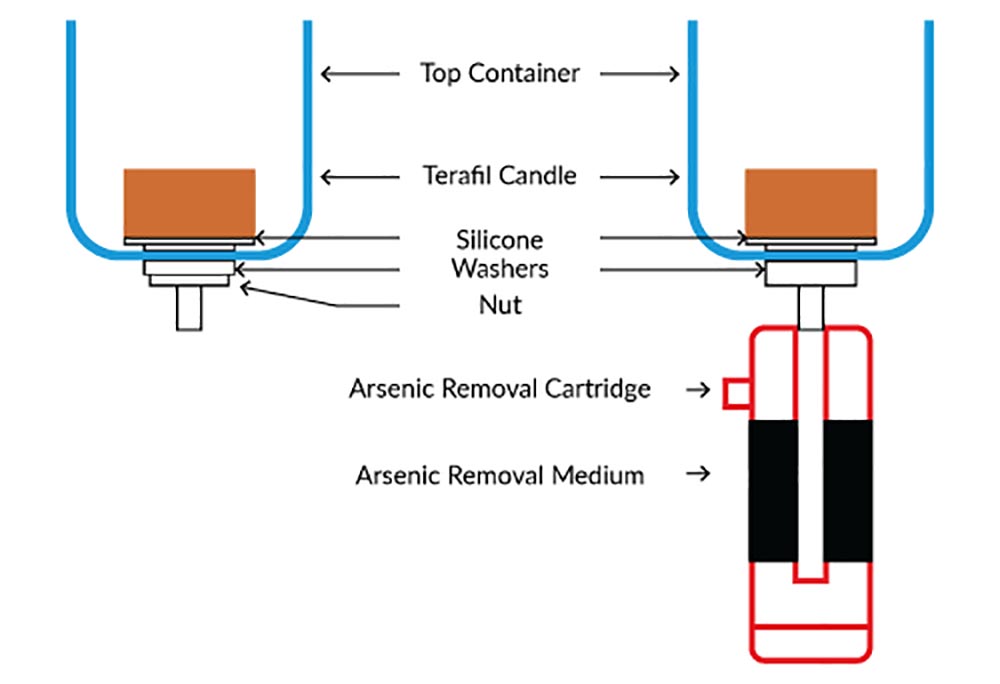

Nano clay particles form the crux of the Terafil candle. The pores in the candles are smaller than the Nano-sized microbes like bacteria and virus, enabling the candles to filter the pathogens in the top layer itself, which enables clean, good water to percolate and pass through it and get dropped into the bottom container. The capillary holes formed within the candle structure are so complex that it does not allow turbid materials, other waste solids, minerals and metal complexes to flow outside its structure. Therefore, the murky water which also has iron particles and pathogens gets filtered and clean water flows down due to gravitational pull and gets collected in the bottom container.

It was essential to build lightweight, quick to make and easy to handle products. Most of the affected population who do not have access to clean water and sanitation live below the poverty line. When we design a product, it is important to take it into consideration: our water purifiers can be fitted by anyone, and there is no need for Annual Maintenance Contract (AMC). Our toilets can be assembled together by anyone that can understand a YouTube tutorial!

We also noticed that other companies provided stand-alone filters but they occupied a lot of space and were packed individually. We thought that instead, thicker buckets or containers could be stacked one inside the other to make transportation to remote villages easier.

Your motto is “Don’t construct toilets, but manufacture toilets” can you explain this further?

Today, India is still lacking 17 million toilets but raw materials are becoming scarce and natural resources depleting. By conventional means, using brick mortar technique with manual masonry, it is highly impossible to provide every household with a toilet, given the cost and manual labour that goes into constructing a toilet. Even the greatest mathematical wizard cannot extrapolate a situation when all these toilets will be built in quick time. This is why we designed ready-to-fit toilets that can be used with no installation time, like planting trees. As a landfill saving measure, we reuse the rejected glass fiber waste dumped by huge windmill blade manufacturers and try to save mother earth and bring down the costs of building toilets as well!

WATSAN’s purpose is to provide water and sanitary solutions to the rural population of India by manufacturing and distributing low-cost, yet effective electricity-free water filters to urban slums and rural families who cannot afford other expensive options.

Website

Chandrasekaran. J, is the Founder & CEO of WATSAN and has been in the industry for more than 27 years. He emerged as the Topper in Plastics Technology and also has profound knowledge in designing, prototyping and manufacturing various products in metals, plastics, and other diverse materials. He currently holds the position of National Consultant for United Nations Industrial Development Organization (UNIDO). He has undergone training after obtaining license from IMMT (CSIR), Bhubaneswar, to manufacture Terafil water filters and proudly holds 3 patents to his credit. Chandrasekaran won the National Award from G.O.I for Innovation in 2012 and 2015.